Trolling in 8 footers. Cruising the out islands. Charging hard through the rough stuff until your first landlubber friend cries for Mommy. However you choose to enjoy your time on the water, your MAHI will help you do just that. All aspects of their design and construction have been conceived to give you years of trouble free, stress free service.

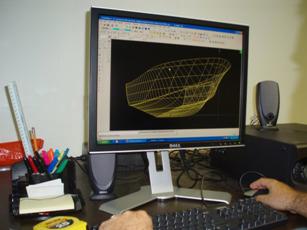

Design & Engineering

At MAHI MARINE we feel strongly that you cannot get a quality boat by just compiling expensive parts and materials. Moreover, quality starts with the complete design and engineering of each component and the vessel as a whole. That is why each new MAHI design begins with a clean computer screen. Using the latest 3d modeling and specialized hull design software, experienced and talented yacht designers create the new model. Nothing gets added unless it has a specific function, nothing is done "just because". Everything is analyzed time and again until we achieve the simplest, strongest, and most efficient structure reasonably possible.

This thinking is quite evident in our hulls. After reading many magazine articles and brochures, you may find that a single number stands out as the most significant indicator of a hull's sea keeping ability, transom deadrise. Although it is a good point of reference, it takes much more than a magic transom deadrise number to make a good running hull. That is why all of MAHI's hull features, such as a variable deadrise bottom, a sharp entry, proper beam to length ratio, center of gravity placement, chine and strake design, and a moderate displacement, blend to create a ride that can only be fully appreciated with a rough water sea trial.

Our arrangements on deck receive the same attention to detail. Like our hulls, comfortable, practical, single level layouts are designed to further reduce fatigue. Lean up against the coamings. They catch you just above the knees. High enough to hook on, low enough to let you reach the water and clear the rod butt. Take note of the cockpit drains. You won't find small diameter hoses, just two big openings right out the hullside. Simple. Strong. Safe. Even speaker and subwoofer locations are planned out for best performance. These features are just a small sample of all the thought that goes into every MAHI design.

Structural and mechanical performance also play an important role in our design process. Every part designed is also engineered to handle the loads experienced boaters know the sea is capable of inducing. Sure, it's not often any good boat has major structural failure, but we feel our extra efforts go a long way torward preventing those little things like gelcoat stress cracks or prematurely corroding hardware.

|

|

|

Construction

Our quality construction begins with precise tooling. There is no substitute for high quality molds. Not only do they provide a superior finish, but they allow for better fitting parts and better consistency. That is why we have all of our tooling done by one of the largest and most talented tooling shops in the country. In house, a vigorous mold maintenance plan assures every MAHI looks as good as the first.

All of the materials going into each MAHI are selected by our engineers, not the bean counters. From the premium gelcoats to electropolished stainless steel hardware, all materials are selected for superior performance and longevity. We know the sea can be brutal on inferior products, that is why only the best goes in a MAHI.

Precisely following drawings and specifications from the design and engineering department, our craftsman are trained to pay particular attention to detail. Laminate overlaps, hatch alignment, wiring, no detail is overlooked.